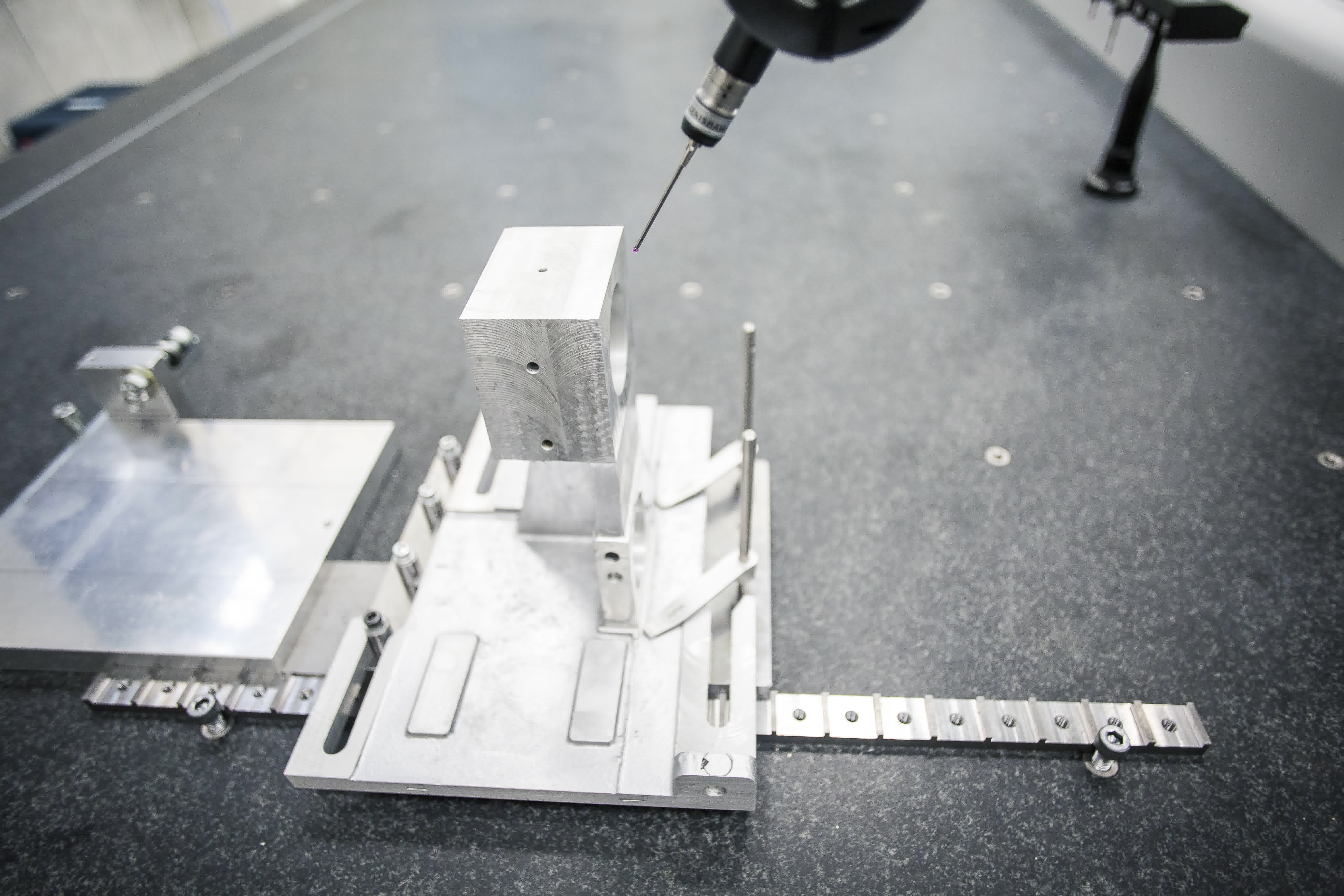

Measuring with coordinate measuring machine

Intro

The coordinate measuring machine is an essential control tool in modern machine manufacturing. Machines with a typically portal design are used to measure complex, high-precision parts with strict tolerances. In recent years, 4S-2000 Ltd. has continuously invested in coordinate measuring machines, as a result of which the five-axis measurement of a part with an enclosure size of up to 1000x1500x800 mm can be realized.

Measuring with a wide range of measuring tools

Intro

In addition to coordinate measuring machines, a lot of other tools help with quality control. At 4S-2000 Ltd., the quality control department performs contour measurement, complex measurement with an altimeter, hardness measurement, roughness measurement; we use a workshop microscope and a projector, furthermore, numerous gauges and digital hand-held measuring devices help the work of the quality department team of seven persons. In addition to the mandatory first-article and final inspection, workers carry out the in-process inspection on an ongoing basis, for which they are provided with suitable tools.

Measurement as a service

Intro

Due to the special measuring machine park, some of our customers use our measuring capacity as a service. Our measuring laboratory is dust-free and air-conditioned; our colleagues welcome the inquiries for measurement of complex pieces with strict tolerances, either for the five-axis coordinate measuring machine, the contour measurer or the hardness tester, just to name the most popular.