Galéria

Charmilles Robofil 290

Bevezető

A svájci gyártmányú huzalszikra gépbe 850 x 500 x 200 mm méretű munkadarab fogható be, 400 x 250 x 200 mm mozgástartományban lehet megmunkálni. A gép 30 fokos maximális kúpos vágási lehetőséggel is rendelkezik, akár 0,5 mm falvastagságú és 0,1-1 mikron pontosságú forgácsolásra képes.

Galéria

Mitsubishi MVR 1200 Connect

Bevezető

A japán gyártmányú huzalszikra gépbe 810 x 700 x 215 mm méretű munkadarab fogható be, 400 x 300 x 220 mm mozgástartományban lehet megmunkálni. A gép 30 fokos maximális kúpos vágási lehetőséggel is rendelkezik, akár 0,5 mm falvastagságú és 0,1-1 mikron pontosságú forgácsolásra képes.

Galéria

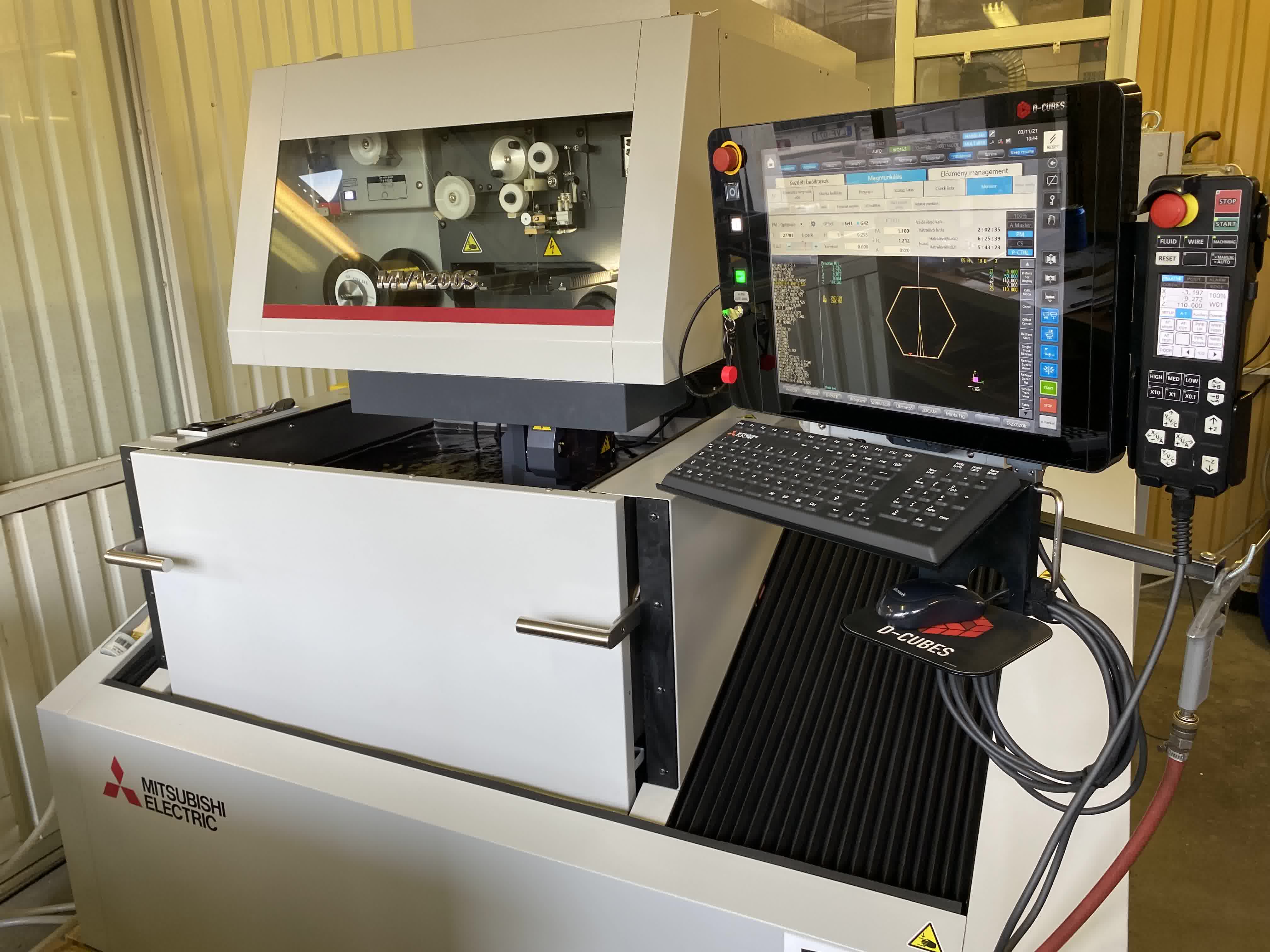

Mitsubishi EA8S

Bevezető

A 64 bit Mitsubischi CNC vezérlésű japán tömbös szikraforgácsológépbe 770 x 490 x 200 mm munkadarab fogható be, a maximális emulziószint 250 mm, a mozgástartomány pedig 300 x 250 x 250 mm . A maximális megmunkálási áramerősség 80 Amper, és legfeljebb 550 kg súlyú alkatrész fogható be.